Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 2025

Brand: LIJIANG GLASS

Applicable Industry: Building Material Shops, Machinery Repair Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Saudi Arabia, Morocco, South Africa, Kazakhstan, Kenya, Indonesia, Canada, Turkey, Argentina, Ukraine, Pakistan, South Korea, Kyrgyzstan, United Kingdom, United States, India, Chile, Nigeria, Uae, Mexico, Italy, Colombia, Uzbekistan, Russia, France, Germany, Tajikistan, Algeria, Spain, Viet Nam, Thailand, Sri Lanka, Japan, Brazil, Philippines, Bangladesh, Australia, Peru, Romania, Malaysia

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Saudi Arabia, South Korea, Ukraine, Chile, Indonesia, Canada, Uae, Kyrgyzstan, Turkey, United Kingdom, Pakistan, Colombia, Nigeria, Uzbekistan, Algeria, India, United States, Italy, Mexico, Sri Lanka, Tajikistan, Russia, France, Germany, Spain, Romania, Japan, Malaysia, Bangladesh, Thailand, Viet Nam, Philippines, Morocco, South Africa, Kazakhstan, Kenya, Australia, Brazil, Argentina, Peru

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

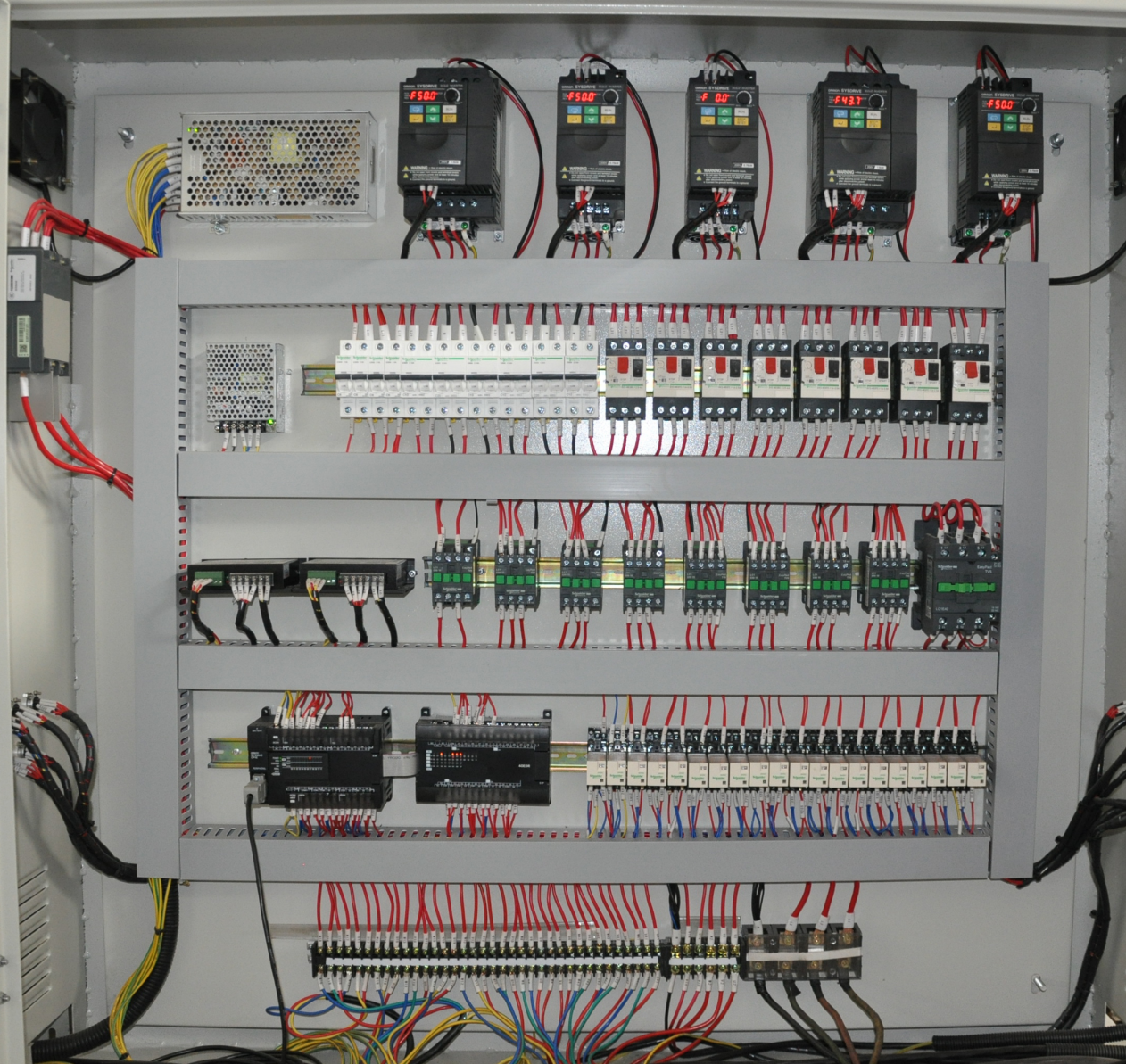

Core Components: Plc, Engine

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-19mm

Certification: Ce

Condition: New

Customized: Customized

Automatic Grade: Automatic

Structure: Vertical

Max. Glass Size: 2500mm*3500mm

Min. Glass Size: 280mm*400mm

Insulating Glass Thickness: 50mm

Packaging: container,wooden

Transportation: Ocean

Place of Origin: China

Supply Ability: 5

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB

Automatic Vertical insulating glass production line adopts the latest technology, its main purpose is to create high-end quality, to provide customers with the latest production technology, improve production efficiency, save production costs and produce maximum benefits.

Automatic insulating glass production line mainly consists of four sections: feeding section, cleaning and drying section, inspection section and closing section. The four sections are placed vertically with the same dip angle, with compact structure, practical economy, high efficiency and convenient maintenance.Automatic insulating glass production line is mainly used for processing and making insulating glass.

Feature of Vertical insulating glass production line

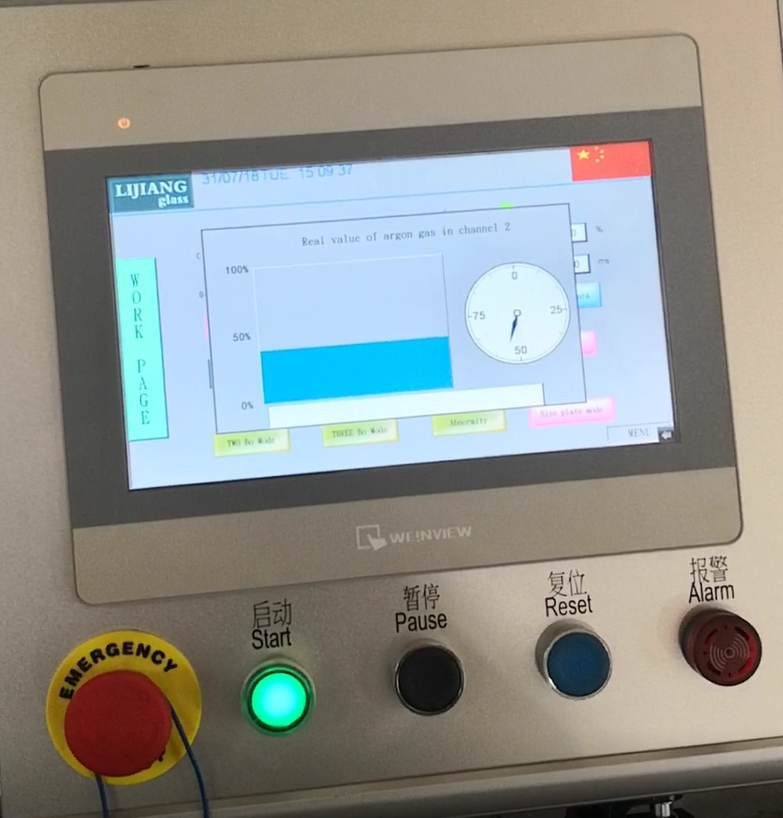

1.Insulating glass production line adopts Siemens control system, equipped with high resolution touch screen.

2.There is the Low-e glass sensor in the washing machine

This sensor is installed before washing machine. It can automatically recognize Low-e glass surface fast and precisely, preventing the glass from dropping Low-e surface.

3.The washing machine uses 304 stainless steel materials

The whole washing and drying section adopt 304 stainless steel materials, including the plate and interior spare parts.

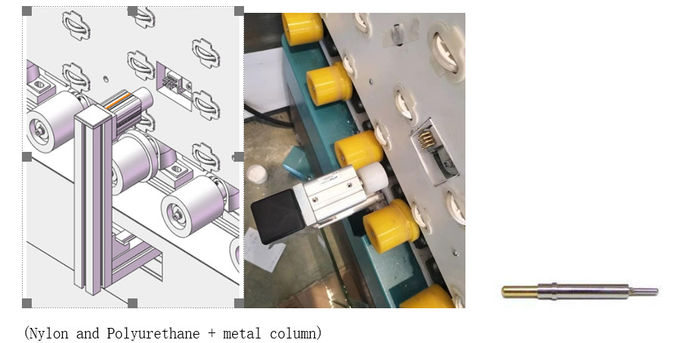

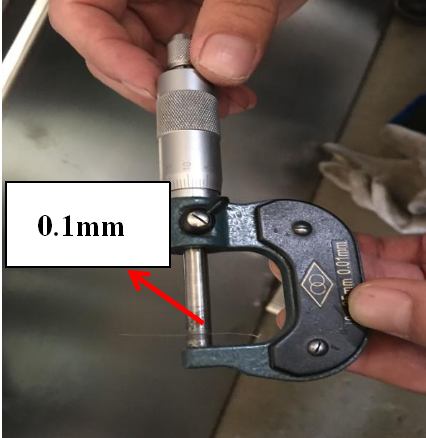

4.The washing machine uses six soft (Low-e) brushes with the 0.1mm diameter only.can wash low-e glass, flat glass, tempered glass and so on. It has a diameter of less than 0.1mm bristles, never damage glass, especially for low-e glass.

5.Air-buffered backrest prevents glass scratches and glass wheel marks

6.The special structure inside the washing machine can automatically recognize glass thickness. Allowing different thicknesses of glass to be transferred quickly, increasing production speed. According to the test, it takes only 22s to produce a 1m*m insulating glass.

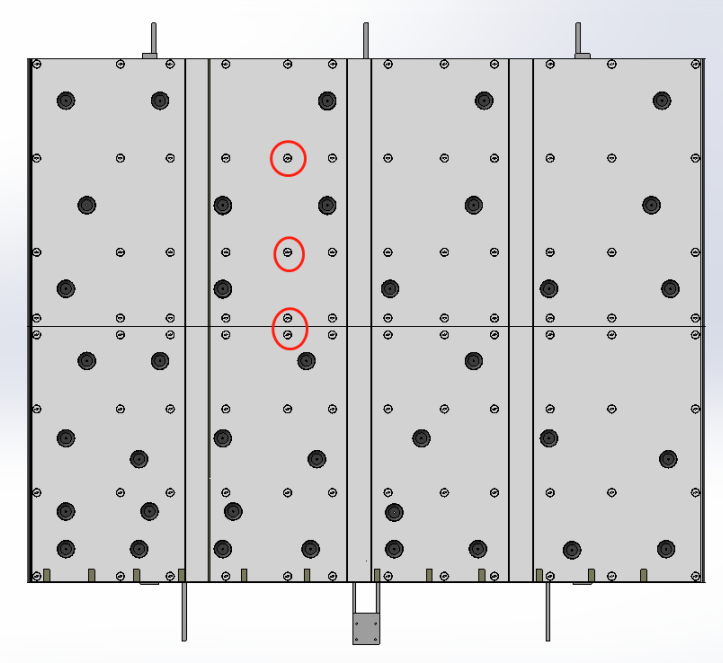

7.We use adjustable points to ensure that the platen will never deform.

We adopt CNC technology into the pressing board. We designed the adjustable points inside the pressing board to keep the back plate straight all the time. In China, except LIJIANG, no one can guarantee that the pressing board will remain vertical and straight all the time after used 10 or 20 years. However, we solve this problem already.

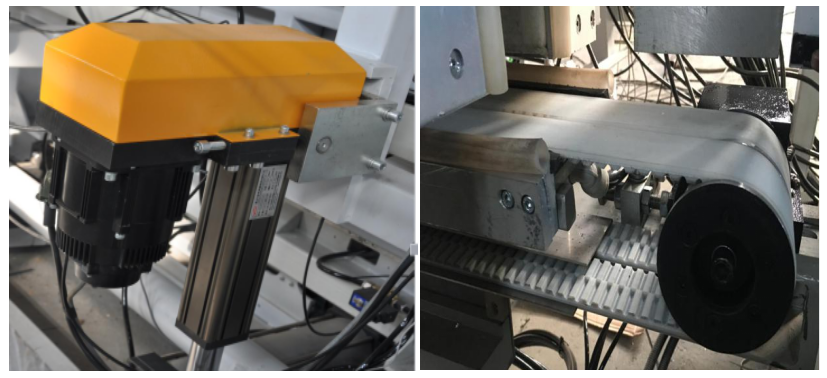

8.The pressing box uses servo motor and timing belt to support pressing IG units.

Servo motor can be accurately calculated the thickness of the glass and aluminum spacer. Compared with traditional hydraulic station, servo motor can guarantee the precise working pressure and protect the glass from damage, at the same time increasing the working speed.

Timing belt is jagged, making the pressing more accuratly.

9.Energy saving of pressing box

The pressing box adopts 3 micro switches, which divide the pressing part into 4 regions.

When each micro switch receives the signal, it will add a part of the working area. When the corresponding micro switch is not touched, the region does not work.

10.Automatic inflating function inside the slab, automatically inflating according to the size of the glass, improving inflation efficiency and gas utilization rate.The IG line fills argon gas with 22s only for one piece of 1m*1m double glazing glass.

Technical data of Vertical insulating glass production line

| Max. glass size | 2500mm*3500mm |

| Min. glass size | 280mm*400mm |

| Glass thickness | 3-19mm |

| Insulating glass thickness | 50mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

Main functions of Automatic insulating glass production line

1)Making double IG units

2)Making triple (3-layer) IG units

3)Making low-e IG units

4)Making shaped IG units

5)Making four-sides IG units

6)Filling argon gas automatically

Company introduction

Jinan Lijiang Automation Equipment Co., Ltd. is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Now, our friendly partners include North Glass, Xin Fuxing, Yaohua, Dalian Huaying, Beijing Guanhua, Shanghai Hao Jing, Sichuan Li Hehua and other well-known enterprises. Since the establishment of the company, our products have been exported to Europe, America, South America, the Middle East, Southeast Asia, India, nearly 30 countries and regions.

other products

1.Double Glazing Glass Production Line

2.Aluminum Spacer Bending Equipment

3.Molecular Sieve Filling Equipment

5.Low-E Glass Edge Grinding Equipment

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line With Gas Filling Online2535

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.