Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: LIAJING

Applicable Industry: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction Works, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Brazil, Malaysia, Sri Lanka, Tajikistan, Romania, Australia, Peru, Canada, Saudi Arabia, Morocco, Bangladesh, South Africa, United Kingdom, Indonesia, Kenya, United States, Pakistan, Argentina, Kazakhstan, South Korea, India, Italy, Mexico, Chile, Ukraine, Kyrgyzstan, Uae, Russia, France, Spain, Colombia, Nigeria, Uzbekistan, Algeria, Thailand, Viet Nam, Philippines

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Brazil, Argentina, Kazakhstan, Ukraine, South Korea, Peru, Canada, Saudi Arabia, Chile, Kyrgyzstan, United Kingdom, Indonesia, Uae, Nigeria, Uzbekistan, Colombia, Pakistan, United States, Italy, India, Algeria, Tajikistan, Mexico, France, Sri Lanka, Russia, Spain, Romania, Malaysia, Australia, Bangladesh, Thailand, Viet Nam, Philippines, Kenya, South Africa, Morocco

Old And New: New

Machine Type: Other

Place Of Origin: China

Certification: Ce, Ce

Warranty Period: 1 Year

Core Selling Point: High-Accuracy

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Glass Bending Machine

Structure: Horizontal

Control System: Plc

Condition: New

Dimension: 10500mm*2200mm*2600mm

Aluminum Spacer Width: 5.5-27mm

Name: Auto Spacer Bending Machine

Max.bending: 2000mm*2000mm (2500mm*2500mm)

Min.bending: 250mm*200mm

Dimensional: ±0.5mm

Processing Speed: ≤26s

Air Supply: ≥0.65mpa

Total Power: Ac220/380v 50hz 2.5kw

Packaging: container

Productivity: 10sets/month

Transportation: Ocean

Place of Origin: China

Supply Ability: 10sets/month

Certificate: CE

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Description of Spacer Frame Bending Machine

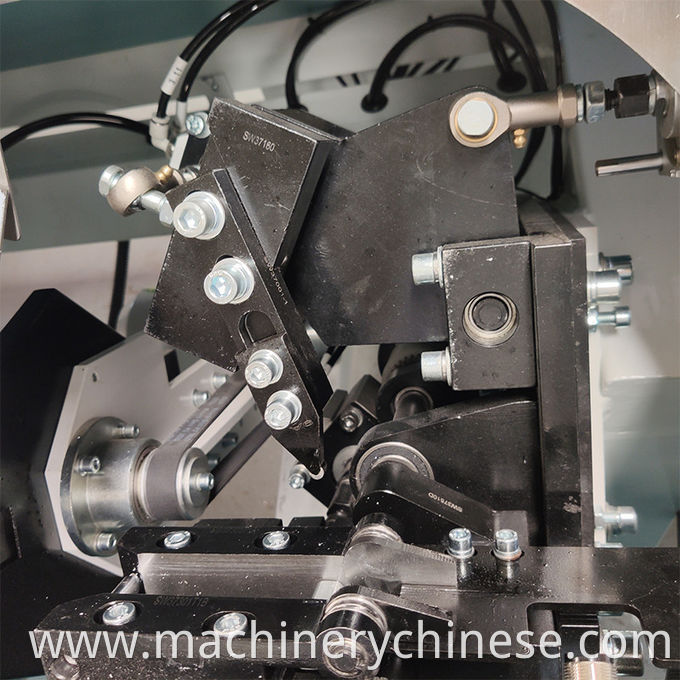

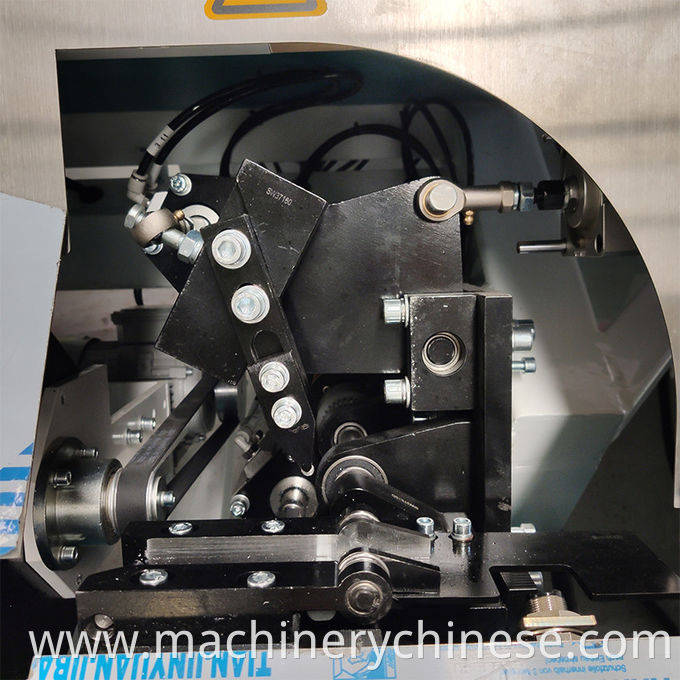

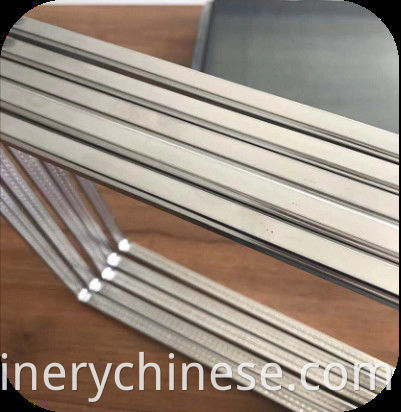

1.Aluminum bar bending machine, color can be customized according to customers, bending Angle accurate, used for insulatin

Corner folding method can greatly improve the service life of middle glass, three less empty corner division accounts for % of the system, corner bending can be a good long system of airtight, lift the service life with the maturity of domestic rich frequency welding can bend aluminum bar, glass life

We for its aluminum bar shape ruler control in the man mm so for the glass beautiful and equipment is made than the station, glass ruler meter =2m, +3m aluminum bar should be made in the main 15m such folded aluminum shape inch to strictly hand the national standard requirements this is suitable for hollow home or equipment manufacturers. 2. Angle error control. During the bending process of aluminum strip, the Angle ruler will change due to the extrusion deformation of the tool head. If the adjustment of the nozzle clearance will cause the thickness of butyl glue coating changes, on the hollow quality. Therefore, the Angle error control after aluminum bar bending is also very important. This point is not reflected in the national standard. According to the practice experience and domestic and foreign application, we believe that the Angle error at least should be ≤0.2mm on the basis of the body error covering the aluminum bar. All glass factories should pay close attention to this Angle when selecting equipment

Equipment details

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | GERMAN SIEMENS | Solenoid valve | Taiwan AIRTAC |

| Servo driver | GERMAN SIEMENS | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Product Categories : Spacer Bending Machine > Aluminum Spacer Bending Machine

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.