Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: Lijiang

Applicable Industry: Building Material Shops

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Italy, Peru, Russia, Morocco, Colombia, South Africa, Uzbekistan, Uae, Australia, Mexico, Brazil, United States, United Kingdom, Philippines, India, Malaysia, Chile, Bangladesh, Nigeria, Kyrgyzstan, Romania, South Korea, Pakistan, Viet Nam, Turkey, Canada, Indonesia, Thailand, Argentina, Sri Lanka, Ukraine, Tajikistan, Kazakhstan, Algeria, Kenya, Spain, Saudi Arabia, Egypt, France

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, France, Saudi Arabia, Spain, Uae, South Africa, Uzbekistan, Tajikistan, Kazakhstan, Colombia, Thailand, Indonesia, Canada, Turkey, Viet Nam, Pakistan, Kenya, Algeria, Argentina, Sri Lanka, Ukraine, Malaysia, Kyrgyzstan, Romania, South Korea, Mexico, Brazil, United States, United Kingdom, Philippines, India, Italy, Peru, Russia, Chile, Bangladesh, Nigeria, Australia, Morocco

Old And New: New

Machine Type: Glass Washing And Drying Machine

Place Of Origin: China

Certification: Ce, Iso

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc, Pump, Motor

Type: Glass Washing And Drying Machine

Structure: Horizontal

Control System: Plc

Glass Washing Machine Type: Horizontal Glass Washing Machine

Maximum Glass Width: 2500mm (Effective Maximum: 2650mm)

Minimum Glass Specification: 400mm×400mm

Glass Thickness: 3mm-25mm (Digital Display)

Speed Range: Glass Thickness Within 3-25mm Vmax=1-12m/Min

Main Drive Brush Speed Regulation Method: Frequency Control

Packaging: container,wooden

Transportation: Ocean

Place of Origin: shandong,China

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR

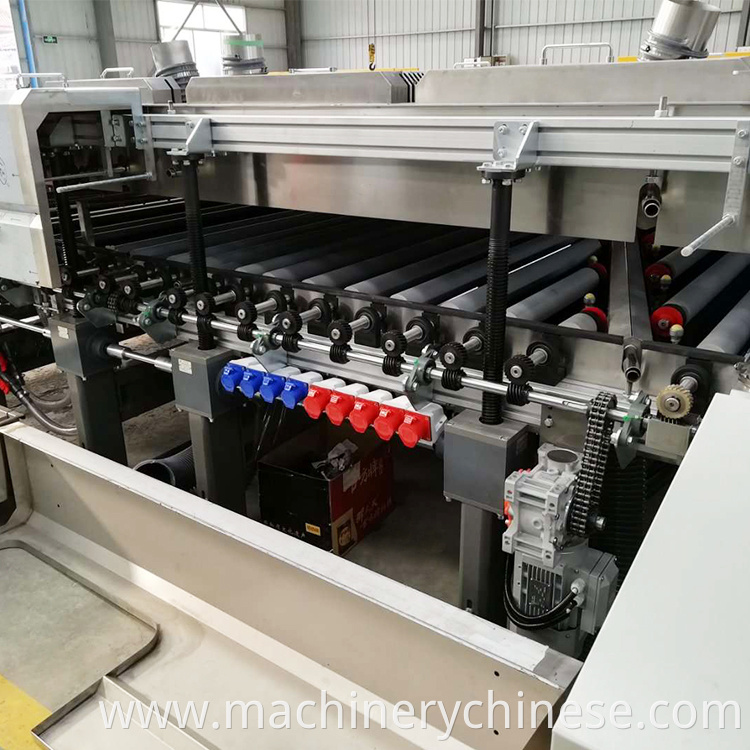

Glass Washing Machine CP-2500A used for cleaning and drying the upper and lower surfaces of ordinary plate glass and high quality low-e glass,it is composed of incoming segment, cleaning air-drying segment and outgoing segment.

1. Aluminum alloy assembled structure, no scrap concept, permanent use,

high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical

paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift: 350mm,easy to clean and maintain;

6. Three pairs of brush(Ø150mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display , the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10.Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11.Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12.Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

1. Maximum glass width: 2500mm (effective maximum: 2650mm)

2. Minimum glass specification: 400mm×400mm (limited to single row on left and right sides)

3. Glass thickness: 3mm-25mm (digital display)

4. Speed range: glass thickness within 3-25mm Vmax=1-12m/min

5. Main drive, brush speed regulation method: frequency control

6. Table height :900±25mm

7. Total power: 42KW(water-bearing wind heating: 15KW)

8. Water source: self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer)

9. Power source: 380V 50Hz

10. Dimensions (length × width × height) : approximately 6260×4800×3100

11. Weight: about 3940kg

Maximum glass width 2500mm (effective maximum: 2650mm) Minimum glass specification 400mm×400mm (limited to single row on left and right sides) Glass thickness 3mm-25mm (digital display) Speed range glass thickness within 3-25mm Vmax=1-12m/min Main drive, brush speed regulation method frequency control Table height 900±25mm Total power 42KW(water-bearing wind heating: 15KW) Water source self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) Power source 380V 50Hz Dimensions (length × width × height) approximately 6260*4800*3100 Weight 3940kg

Silicone Sealant Sealing Robot

Spacer Bending Machin

OTHER PRODUCT:

Product Categories : Glass Washing Machine > Horizontal Glass Washing Machine

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.