Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: Jinan LIJIANG Glass

Applicable Industry: Hotels, Machinery Repair Shops, Home Use, Energy &Amp; Mining, Retail, Garment Shops, Building Material Shops, Food &Amp; Beverage Factory, Food Shop, Food &Amp; Beverage Shops, Other, Printing Shops, Farms, Manufacturing Plant, Restaurant, Construction Works, Advertising Company

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Tajikistan, Kazakhstan, Algeria, Kenya, Spain, Saudi Arabia, France, Egypt, Canada, Indonesia, Thailand, Argentina, Sri Lanka, Ukraine, Kyrgyzstan, Romania, South Korea, Malaysia, Pakistan, United Kingdom, Philippines, India, Viet Nam, Turkey, Chile, Bangladesh, Nigeria, Uzbekistan, Australia, Uae, South Africa, Colombia, Morocco, Russia, Peru, Italy, United States, Brazil, Mexico

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, France, Saudi Arabia, Spain, Uae, South Africa, Uzbekistan, Tajikistan, Kazakhstan, Colombia, Thailand, Indonesia, Canada, Turkey, Viet Nam, Pakistan, Kenya, Algeria, Sri Lanka, Ukraine, Malaysia, Kyrgyzstan, Argentina, India, Philippines, United Kingdom, South Korea, Romania, Nigeria, Australia, Mexico, Brazil, United States, Italy, Peru, Russia, Chile, Bangladesh, Morocco

Old And New: New

Machine Type: Glass Washing And Drying Machine

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-25mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Pressure Vessel, Pump, Engine, Motor, Gearbox, Other, Bearing, Gear, Plc

Name: Horizontal Glass Cleaning Machine

Type: Ktwq-2500c

Max.Glass Size: 2500*3660mm

Min Glass Size: 450*280mm

Glass Washing Speed: 2-10m/Min

Working Table Height: 900mm±30mm

Blower Power: 22kw

Processing Speed: 0.5~12m/Min

Packaging: Wooden Cases Package and Container Transfer

Productivity: 15 Sets Per Month

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: Jinan City, Shandong Province, China

Supply Ability: 15 Sets Per Month

Certificate: CE & iSO9000

Port: Qingdao Port

Payment Type: Paypal,D/A,D/P,T/T,L/C,Others

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

| Item. | Parameter. |

| Max. width | 2500mm |

| Min. size | 400*400mm |

| Glass thickness | 3~28mm |

| Working table height | 900mm±30mm |

| Blower power | 22kw |

| Total power | 32kw |

| Weight | 3000kg |

| Dimension | 5700*3300*2500mm |

| Low-e require | Yes |

| Water heater | Yes |

| Processing speed | 0.5~12m/min |

| Processing-speed suggestion as follow: | |

| 4mm~8mm thickness, speed suggested to 8-12m/min | |

| 10mm~12mm thickness, speed suggested to 4~6m/min | |

| 15mm~19mm thickness, speed suggested to 2-3m/min | |

| 20mm and more, speed suggested to 0.5-1.5m/min | |

| Item. | Spec. |

| Main machine frame | Aluminum alloy + steel, no deformation. |

| High pressure pump | China famous brand: Shanqing |

| Frequency converter of conveying | China famous brand: Kailida |

| Brush motor | China famous brand: Jinxing |

| Bearing | China famous brand: HRE |

| Electrical Appliance | Schneider |

| Rubber roller | NBR Perduran(sour liquid forbiddion), stainless steel 304 shaft |

| Water tank, sink, side covers, all parts touch water | Stainless steel 201 |

| PLC | Siemens |

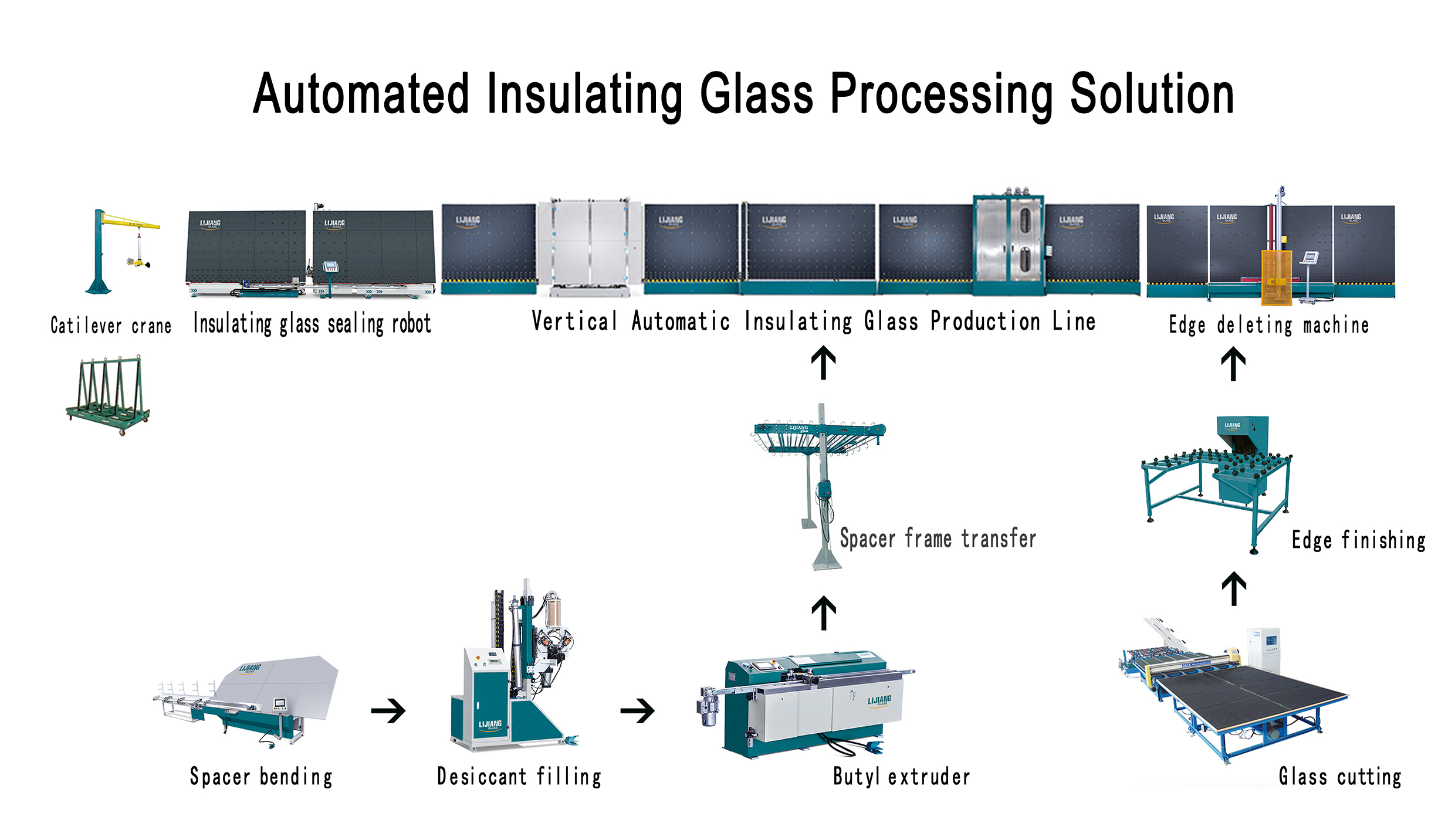

Insulating Glass Production Line

Spacer Bending Machine

Desiccant Filling Machine

Butyl Extruder Machine

Automatic Low-E Glass Deletion

Product Categories : Glass Washing Machine > Horizontal Glass Washing Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.