Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Kation003A

Brand: Kation

After-sales Service: Other

Engineering Solution Capability: Others

Application Scenario: Hotel, Park, Apartment, Office Building, Hospital, School, Mall, Living Room, Bedroom, Leisure Facilities, Supermarket

Design Style: Chinese, Japanese, Mediterranean, Minimalist, Modern

Place Of Origin: China

Fast Charge Agreement: Low-E Glass

Shape: Flat

Structure: Hollow

Packaging: container or paper case

Transportation: Ocean,Air

Place of Origin: China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

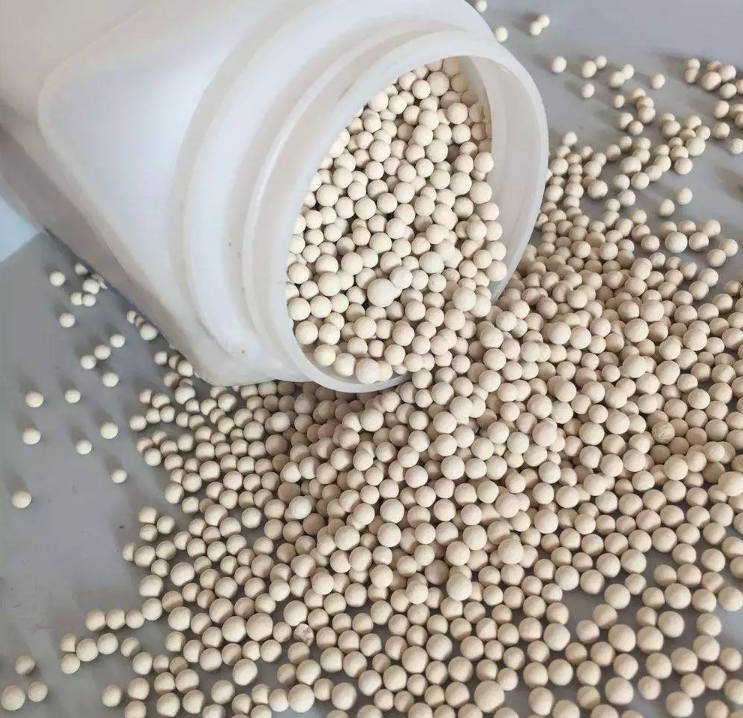

Molecular Sieve type 3A is an alkali metal alumino-silicate; it is the potassium form of the type A crystal structure. Type 3A has an effective pore opening of about 3 angstroms (0.3nm). This is large enough to allow in moisture, but excludes molecules such as unsaturated hydrocarbons which can potentially form polymers; and this maximizes lifetime when dehydrating such molecules.

3A - Zeolites are available in beads of 1-2 mm,( 58413760, 58413739,10x18 mesh) 2-3 mm,( 58413761, 58413740,8x12 mesh) , 2.5-5 mm,( 58413762, 58413741,4x8 mesh) and as powder, and in pellet 1.6”, 3.2”.

| Package Type | Container Load Capacity | Delivery time | Quality Insurance | Payment Terms | |

| 20 GP | 40 GP | ||||

| Steel drum, 150kg/drum | 12000 kg | 24000 kg | Within 7-10 days | Chinese National Standard; Offer quality assurance as request. | T/T, L/C, Paypal, West Union |

Typical Application

Typical Chemical Formula

0.4K2O 0.6Na2O Al2O3 2.OSiO2 4.5H2O

SiO2 : Al2O3 ≈2

Regeneration

Molecular sieve Type 3A can be regenerated by either heating in the case of thermal swing processes; or by lowering the pressure in the case of pressure swing processes.

To remove moisture from a 3A molecular sieve, a temperature of 200-230°C is required. A properly regenerated molecular sieve can give moisture dew points below -100°C.

The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

Size

Packaging & Delivery

Packaging Details25KG or 30KG carton packing, inner vacuum packing.

25KG or 30KG cardboard bucket packing, inner vacuum packing.

50KG or 150KG Iron bucket packing, inner vacuum packing.

Or can be customized as your demand.

As professinal Insulating Glass Machine manufacture in China,except material such as Moleculaer sieve and aluminum spacer and sealant . We are good at develping and producing automatic vertical insulaing Glass Processing Production Line ,vertical low-e glass egde deleting machine,automatic robot insulaiting glass production line and so on.

OTHER PRODUCT

1.Insulated Glass Production Line

3.Glass Edge Finishing Machine

4.Vertical Glass Washing Machine

5.Molecular Sieve Filling Equipment

Product Categories : Insulating Glass Materials

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.