Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

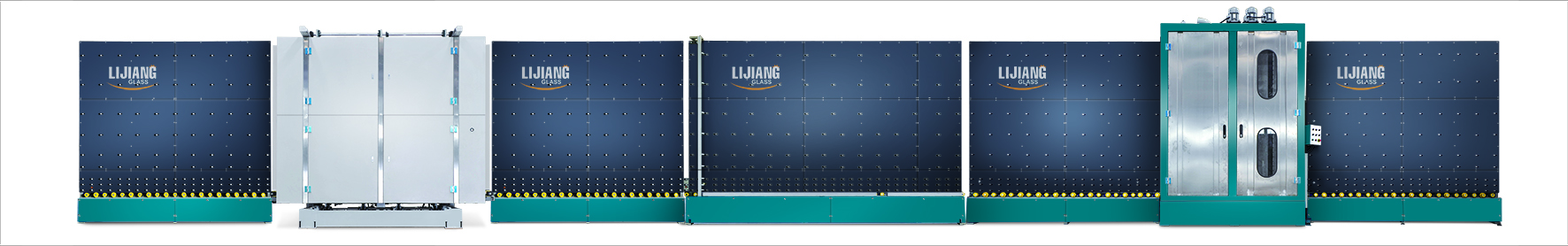

Model No.: LJBZ2025

Brand: LIJIANG

Type: Insulating Glass Production Line

Certification: UR

Structure: Vertical

Control System: PLC

Glass Washing Machine Type: Ultrasonic Glass Washing Machine

Glass Edging Machine Type: Glass Beveling Machine

Grinding Head Number: 9

Condition: New

Machine Weight: 5000KG

Air Pressure: ≥0.8Mpa

Max Glass Size: 2000*3000MM

Glass Thickness: 3-15mm

Glass Washing Speed: 2-10m/min

Min Glass Size: 450*280mm

Dimension: 23500*3500*3700mm

Double Glass Thickness: 50mm

Washing Brushes: Low-e Soft Brueshes

Machine Name: Vertical Insulating Glass Production Line

Packaging: wooden box

Productivity: 10 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10set

Certificate: CE

HS Code: 8464901900

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

As the most important process of insulating glass production, we are especially professional in glass cleaning, transmitting pressing and gas filling.The production line can do double glass,triple glass and stepped glass.

As the most important process of insulating glass production, we are especially professional in glass cleaning, transmitting pressing and gas filling.The production line can do double glass,triple glass and stepped glass.

1, To Avoide the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent)

2, three pairs soft brushes can wash low-e glass and normal glass , the diameter is less than 0.1mm.

3, Materials are stainless steel.

4, Air knife is float design , it always keep the right and suitable distance 3mm between the glass surface and air knife (Same like LISEC structure ) check the following picture. (3mm is the best drying distance)

5, The front and back side squeeze wheel are all actively moved and convey. No mater the glass size is big /small or thickness different(8mm) , it all guarantee the glass pass through smoothly.(Same like LISEC)

6, There have stress after welding in the Pressing frame ,

so the out-of -shape problems is inescapable after using some time

(machine can not press DGU properly evenly and tightly )

that is not good for IGU quality, any glass project can not accept these products

7,For this uneven inescapable issue, here are our solution :

a. we all do the aging treatment , it’s the stress-remove by vibration failure device.

b. The important is We design the 74 points on the backbord, if there have any out-of shape problems we can adjust easily at any time. ( same like Bystronic structure )

8, Input the argon gas concentration into touch screen according to customer required

9, Display Function : touch screen will display whole argon gas filling processing , you will know very clear how much already argon gas filed inside

We are the first and the only one company who can show the argon percentage on the touch screen on line,its very useful for customer,When it reach the data customer set ,It will alarm and stop automatically

10, GAS filling from bottom and it was designed separately for saving gas .

A: The pressing part was devided into 4 part , (per 800mm), when the small size glass(less than 800mm) pass through the pressing and gas filling section, ,only one part work.if more than 800mm but less than 1600mm,it will two parts work, no need the whole press and gas filling section work. it can save the argon gas.

| Components | Brand | Remark |

| Servo motor | Germany Simens | For stepped glass |

| Servo driver | Germany Simens | For stepped glass |

| Servo motor | Germany Simens | For transfer |

| Servo motor | Germany Simens | For press |

| PLC | Germany Simens |

|

| Low voltage component | Germany Simens |

|

| Germany Simens |

| |

| Taiwan MW |

| |

| Korea Autonics |

| |

| Taiwan Airtac |

| |

| Taiwan Airtac |

| |

| Touch screen | Taiwan Wenview |

|

| Taiwan (TEND) |

| |

| Relay | Japan Omron |

|

| Button and indicator light | French Schneider |

|

| Max.glass size | Normal glass | 2500*3500mm/2000*2500mm

|

| Glass with argon gas | 2500*3200mm/2000*2500mm | |

| Min.glass size | 280*450mm | |

| Glass thickness | 3-15mm | |

| Insulating glass thickness | 50mm(special made for 60mm) | |

| Glass washing speed | Summer 8-10m/min winter 6-7m/min | |

| Glass conveyor speed: | 45m/min | |

| Washing brushes | 3 pairs | |

| Water supply: | Water consumption:0.5t/h conductivity:≤50μs/cm6-7 | |

| Air supply | Flow: 0.8m/min | |

| Air pressure | ≥0.8MPa | |

| Total power | 3P380V 50HZ 34KW | |

| Dimension | 23500*3500*3700mm | |

Company Profile

JINAN LIJIANG QUTOMATIC EQUIPMENT CO.LTD is an enterprise which integrated DGU Machines development, designing, sale and service into a whole. The company is located in the beautiful spring city, Jinan. Because it is close to Beijing-shanghai high-speed railway line, it’s very convent for transportation.

The company adheres to the “Hi-Q products”. We are striving to create the top-grade DGU Machines through setting up technology research and development center, inviting some experts to guide. We also cooperate with the domestic well-know enterprises and actively import foreign advanced technology. Now our company are the main supplier of glass deep processing enterprises in China. Our DGU machines are used by the main domestic famous glass factories, such as NORTH GLASS, XIN FU XING GLASS,YAO HUA GLASS, DALIAN HUAYING GLASS etc. We also have more than 400 customers who use our DGU machines in China. We have got CE certification in 2017. So far our machines has exported to more than 30 countries and regions, just like Europe, South America, Middle East, Southeast Asia and so on.

At the same time, our company cooperates with scientific research institution, which is based on research and development center, imported advanced intelligence. Our company successively cooperates with institution of China North Industries Group and Shandong University in order to develop more new products. Now we have already successfully produced vertical Insulating Glass Production Line, vertical Insulating Glass Sealing Robot and New Butyl Extruder Machine, which quality has reached the domestic top-grade level.

LIJIANG GLASS are goes into a leading way in the DGU mechanical field with the advanced technology, first-class products, perfect service and good reputation!

We have our own technician team ,IG line and Automatic Sealing Robot technician team have 6 experts which all have more than 15 glass machine working experience. Aluminum spacer bending and Desiccant Filling Machine team we have 3 technician which have rich experience in double glass machines. Butyl Extruder Machine and sealing pump and Hot Melt Machine team have 4 experienced technician, all of them are worked in glass machine filed more than 12 years,

National Glass Expo :

Glasstec in Germany

CAM Eurasia Glass in Istanbul

India Zak, India Glasspro,

Glasstech Aisa ,

Glass build in America, Mexico glass expo .

Big Five In Dubai, Egpyt.

Domestic glass expo : China glass ,( 58313233, 58313171,Beijing /shanghai), Guangzhou.

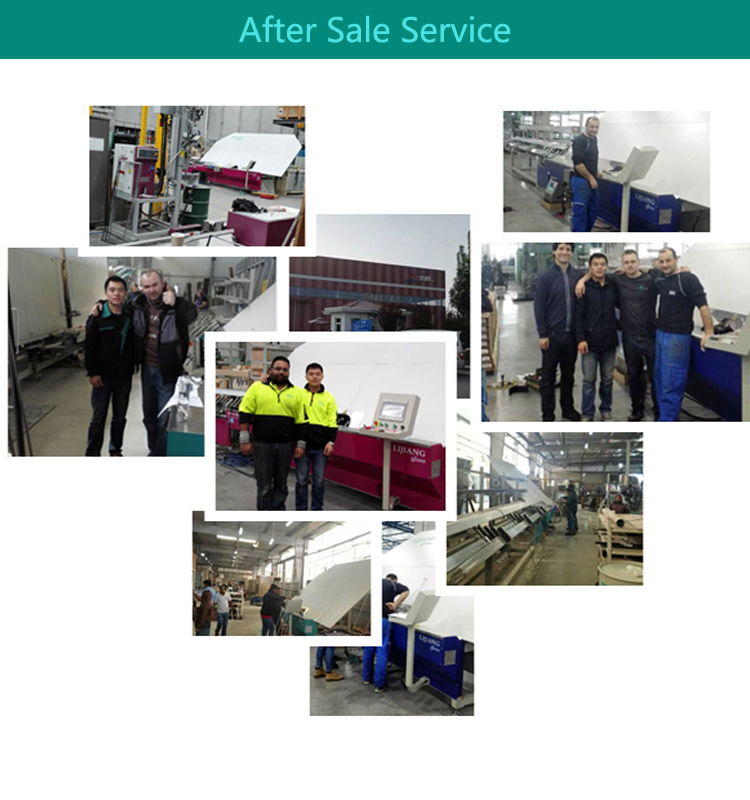

We have our own china domestic team and oversea service team .

Whole team was included by 15 china engineers who worked in glass machine filed more than 20 years and 5 oversea engineers , two of them from india and others from south America and midle east.

24 hours online service and local engineer available , guarantee customers got timely service and solution .

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line With Gas Filling Online2535

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.