Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJBZ2535

Brand: LIJIANG GLASS

After-sales Service: Online Technical Support, Other, Onsite Installation, Onsite Training, Onsite Inspection, Free Spare Parts, Return And Replacement

Engineering Solution Capability: Others, Cross Categories Consolidation, Total Solution For Projects, 3d Model Design, Graphic Design

Application Scenario: Workshop

Design Style: Modern, Industrial

Place Of Origin: China

Fast Charge Agreement: Acid Etched Glass, Insulated Glass, Low-E Glass, Heat Reflective Glass, Heat Absorbing Glass, Decorative Glass, Bulletproof Glass

Shape: Flat, Curve

Structure: Hollow, Solid

Production Process: Clear Glass, Tempered Glass, Tinted Glass, Painted Glass, Coated Glass, Wired Glass, Figured Glass, Frosted Glass, Laminated Glass, Stained Glass

Variety: Float Glass, Glass Block, Glaverbel Glass, Sheet Glass

Warranty: 1 Year

Max Glass Size: 2500*3500

Min Glass Size: 280*400

Machine Brand: Lijiang Glass

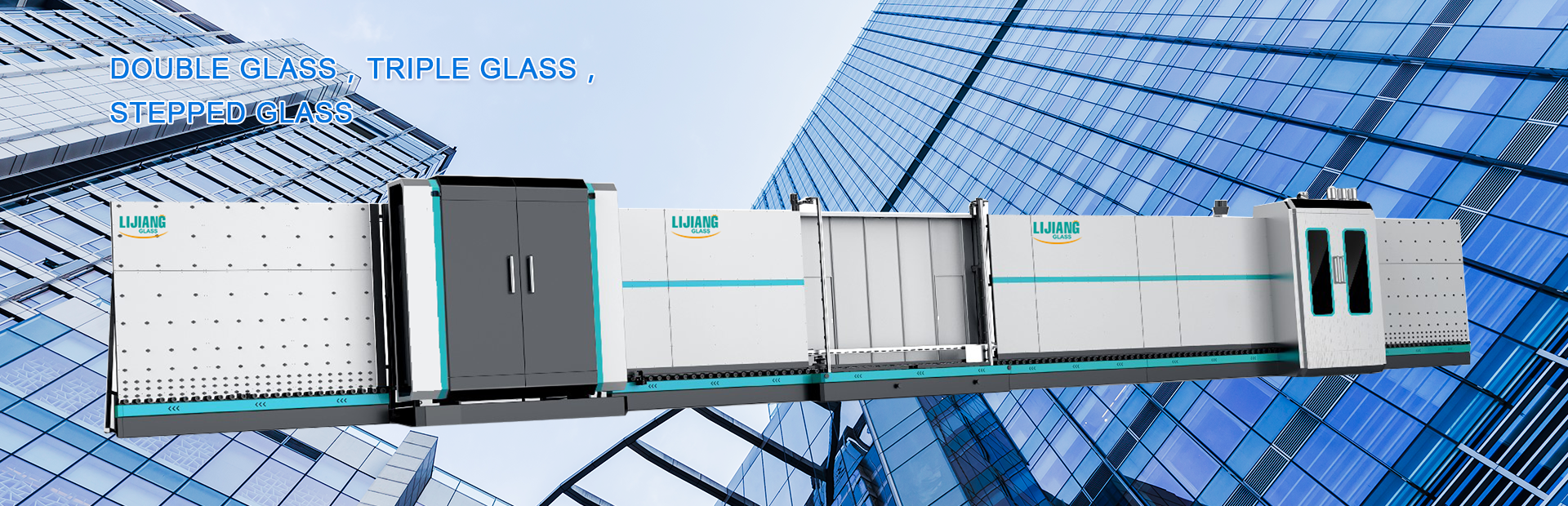

Machine Name: Insulated Glass Processing Machine

Total Length: 23.5 Meters

Glass Thickness: 50 Mm

Packaging: Containers /wooden box

Productivity: 700 - 800 pieces

Transportation: Ocean

Place of Origin: JINAN CHINA

Supply Ability: 500 SETS

Certificate: CE

HS Code: 8464901900

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Insulating glass processing machine with washing and pressing machine

Insulating glass equipment includes cutting equipment / grinding equipment / washing and drying machine / bending machine / filling machine or glue machine.

The insulating glass processing line contains washing machine, pressing machine, loading and unloading machine, with filling argon gas online.

Main Features:

• The line has 7 sections:

01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.

• PLC control system, touch screen interface

• Using Siemens servo motors

Applicable to produce double glass, triple glass

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• Pre-washing (Optional)

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

Features of the filling gas part :

• Ultra-long (2500mm*3500mm) insulating glass can be compressed twice

• Adopts conveyor belt to transfer glass, uses servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• Automatically fill argon gas with significant sealing effect, higher argon content

• Set zones to fill different size of glass with follow-up sealing method reduces argon loss

• Can set gas value and show the process of filling gas on the touch screen

Technical data

| Max. glass size | 2500mm*3500mm |

| Max glass size for filling gas | 2500mm*3200mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

Relative products:

Double Glass Processing Machine

Warm Edge Spacer Bending Machine

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line With Gas Filling Online2535

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.