Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJBZ2535G

Brand: LIJIANG GLASS

Handle Material: Stainless Steel

Warranty: 1 Year

Max Glass Size: 2500*3500

Min Glass Size: 280*400

Max Glass Size For Filling Argon Gas: 2500*3200

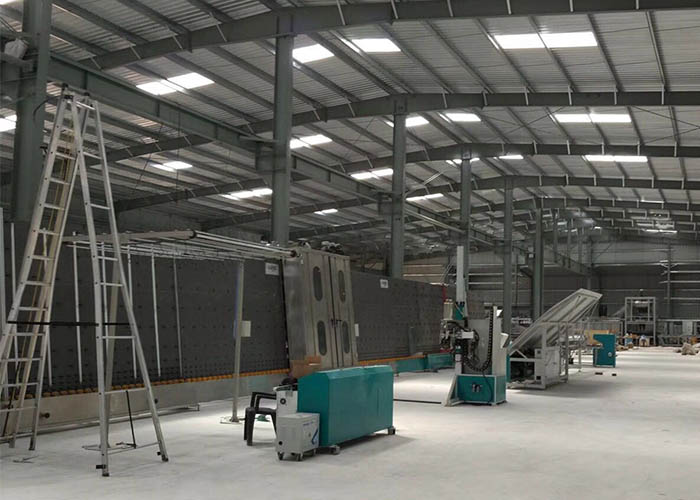

Total Length: 23.5 Meters

Name: Insulating Glass Processing Line

Float Glass Size: 3 - 15 Mm

IG Thickness: 60 Mm

IG Types: Double / Triple / Step Glass

Packaging: Containers

Productivity: 700 - 800 pieces

Transportation: Ocean

Place of Origin: JINAN CHINA

Supply Ability: 500 SETS

Certificate: CE

HS Code: 8464901900

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Since the virus of the whole world, Our engineers are restricted to many countries in the world. So we provide installation service and training work online by WECHAT, WHATSAPP and so on. Once the world has a better situation, our engineer will go to check our machines again.

5. The details of the IG line ?

Details introduce of the LJBZ2545

• 01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

• 02 washing machine

Main feature:

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

• 03 discharge section

• 04 inspection and installation section

• 05 transfer section

• 06 pressing and filling section

Main feature:

• Ultra-long glass can be compressed by twice

• Adopts conveyor belt to transfer glass, use servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• 07 discharge section

• Storage glass

• Can be connected to sealing machine

Technical data

| Max. glass size | 2500mm*4500mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ |

| Dimension | 23500*3500*3700mm |

Electrical parameters

| NAME | ORIGIN | BRAND |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Servo motor for step glass | Japan | FUJI |

| Photoelectric switch | Germany | SICK |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| Touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Brush motor | China | QINGHUA |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line With Gas Filling Online2535

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.