Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

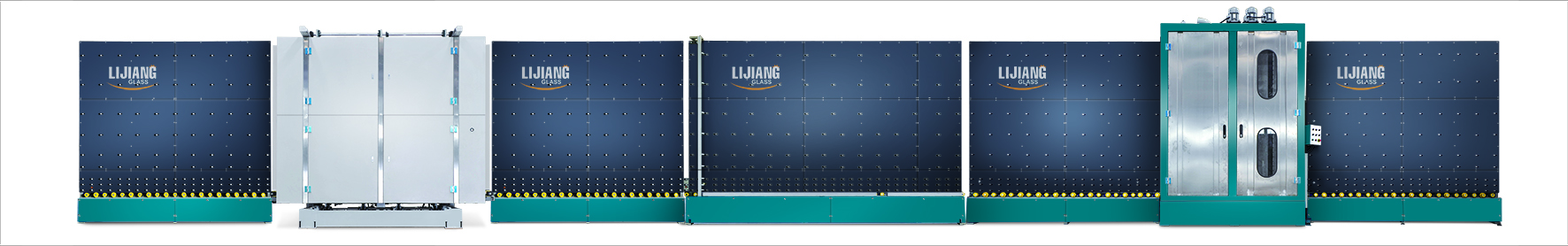

Model No.: LJBZ2025

Brand: Lijiang

Applicable Industry: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Other, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Brazil, Malaysia, Sri Lanka, Tajikistan, Romania, Australia, Peru, Canada, Turkey, Saudi Arabia, Morocco, Bangladesh, South Africa, Kenya, United Kingdom, Indonesia, United States, Pakistan, Argentina, Kazakhstan, South Korea, India, Italy, Mexico, Chile, Ukraine, France, Russia, Germany, Spain, Colombia, Nigeria, Uae, Kyrgyzstan, Uzbekistan, Algeria, Thailand, Viet Nam, Philippines, Japan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Brazil, Argentina, Kazakhstan, Ukraine, South Korea, Peru, Canada, Turkey, Saudi Arabia, Chile, Kyrgyzstan, Nigeria, Uae, Indonesia, United Kingdom, United States, Pakistan, Colombia, Uzbekistan, Tajikistan, Algeria, India, Italy, Mexico, Sri Lanka, Japan, France, Russia, Spain, Germany, Romania, Malaysia, Australia, Bangladesh, Thailand, Viet Nam, Philippines, Kenya, South Africa, Morocco

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-18mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Other

Core Component Warranty Period: 1 Year

Core Components: Pressure Vessel, Motor, Other, Bearing, Gear, Plc, Pump, Engine, Gearbox

Brand Name:: Jinan Lijiang Glass

Machine Type:: Insulating Glass Production Line

Process Glass Size Max: 2500×1800mm

Process Glass Size Min: 450×450mm

Original Glass Thickness: 3~12mm

Washing Speed: 6.5m/Min

Conveying Speed After Washing: 15~32m/Min

L×W×H (mm): 16000×2000×2850

Net Weight: 5000kg

Power Supply: 380v 50hz

Packaging: container

Transportation: Ocean,Land,Express,Air,Others

Place of Origin: jinan

Supply Ability: 10sets-month

Certificate: ce

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal,Others

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

1, To Avoide the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent)

2, three pairs soft brushes can wash low-e glass and normal glass , the diameter is less than 0.1mm.

3, Materials are stainless steel.

4, Air knife is float design , it always keep the right and suitable distance 3mm between the glass surface and air knife (Same like LISEC structure ) check the following picture. (3mm is the best drying distance)

5, The front and back side squeeze wheel are all actively moved and convey. No mater the glass size is big /small or thickness different(8mm) , it all guarantee the glass pass through smoothly.(Same like LISEC)

6, There have stress after welding in the Pressing frame ,

so the out-of -shape problems is inescapable after using some time

(machine can not press DGU properly evenly and tightly )

that is not good for IGU quality, any glass project can not accept these products

7,For this uneven inescapable issue, here are our solution :

a. we all do the aging treatment , it’s the stress-remove by vibration failure device.

b. The important is We design the 74 points on the backbord, if there have any out-of shape problems we can adjust easily at any time. ( same like Bystronic structure )

8, Input the argon gas concentration into touch screen according to customer required

9, Display Function : touch screen will display whole argon gas filling processing , you will know very clear how much already argon gas filed inside

We are the first and the only one company who can show the argon percentage on the touch screen on line,its very useful for customer,When it reach the data customer set ,It will alarm and stop automatically

10, GAS filling from bottom and it was designed separately for saving gas .

A: The pressing part was devided into 4 part , (per 800mm), when the small size glass(less than 800mm) pass through the pressing and gas filling section, ,only one part work.if more than 800mm but less than 1600mm,it will two parts work, no need the whole press and gas filling section work. it can save the argon gas.

| Components | Brand | Remark |

| Servo motor | Germany Simens | For stepped glass |

| Servo driver | Germany Simens | For stepped glass |

| Servo motor | Germany Simens | For transfer |

| Servo motor | Germany Simens | For press |

| PLC | Germany Simens |

|

| Low voltage component | Germany Simens |

|

| Germany Simens |

| |

| Taiwan MW |

| |

| Korea Autonics |

| |

| Taiwan Airtac |

| |

| Taiwan Airtac |

| |

| Touch screen | Taiwan Wenview |

|

| Taiwan (TEND) |

| |

| Relay | Japan Omron |

|

| Button and indicator light | French Schneider |

|

| Max.glass size | Normal glass | 2500*3500mm/2000*2500mm

|

| Glass with argon gas | 2500*3200mm/2000*2500mm | |

| Min.glass size | 280*450mm | |

| Glass thickness | 3-15mm | |

| Insulating glass thickness | 50mm(special made for 60mm) | |

| Glass washing speed | Summer 8-10m/min winter 6-7m/min | |

| Glass conveyor speed: | 45m/min | |

| Washing brushes | 3 pairs | |

| Water supply: | Water consumption:0.5t/h conductivity:≤50μs/cm6-7 | |

| Air supply | Flow: 0.8m/min | |

| Air pressure | ≥0.8MPa | |

| Total power | 3P380V 50HZ 34KW | |

| Dimension | 23500*3500*3700mm | |

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line2025

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.