Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: **

Brand: LIJIANG GLASS

Applicable Industry: Building Material Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, Uae, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Kenya, Argentina, South Korea, Chile, Uae, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia, Morocco

Old And New: New

Machine Type: Other

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 1-40mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor, Plc, Pump

Glass Thickness: 3-15mm

Power: 5.7kw

Voltage: 380v 50hz

Dimension(L*W*H): 2800*700*900mm

Weight: 650 Kg

Packaging: Wooden boxes and containers

Productivity: 10 units per month

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 10 units per month

Certificate: CE

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

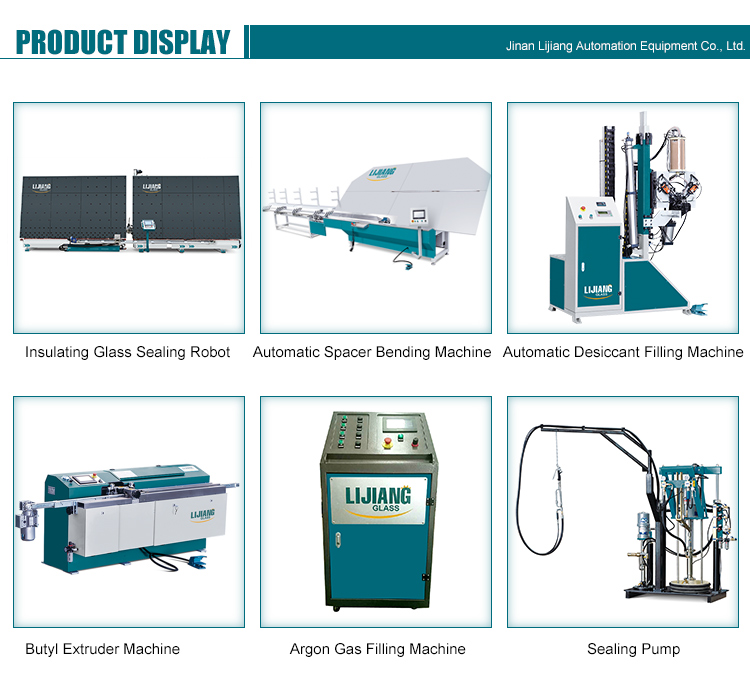

Jinan LIJIANG Glass LJTB01 Butyl Extruder Machine

1. This machine adopts microcomputer PLC, touch screen control, simple operation, and a high degree of automation;

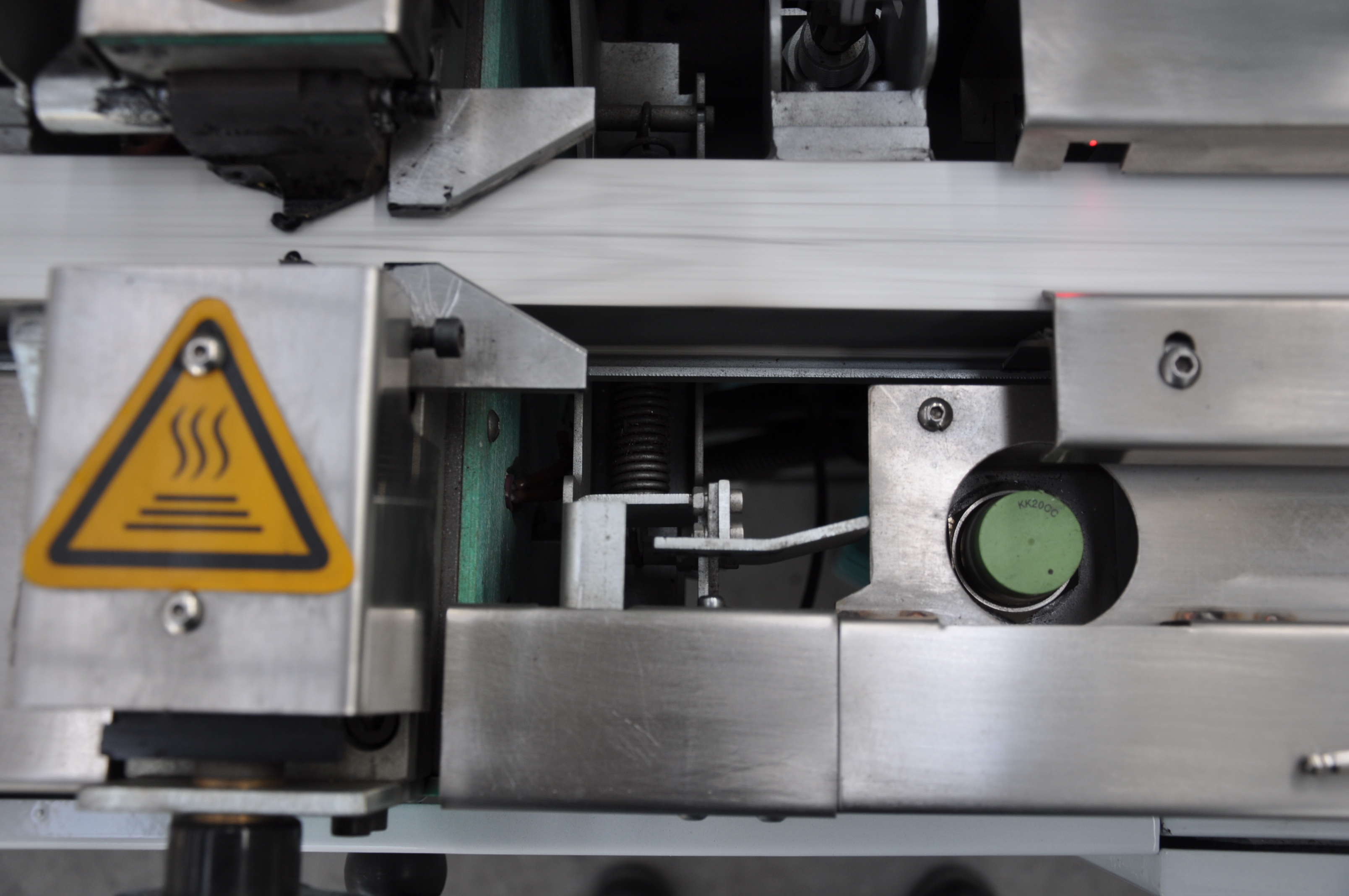

2. Using wear-resistant alloy steel coating head, coating control accuracy and service life are greatly improved;

3. The overall translational coating adjustment bracket is adopted, and the repeat positioning accuracy is high;

4. With automatic tracking, display, and storage functions of glue volume, it is convenient and fast to operate and use;

5. The glue supply amount of the metering pump is automatically calculated by the coating width and glue amount input by the operator, and the glue supply amount can be modified according to the characteristic curve of the metering pump;

6. The surface coating adopts a sealed flexible stainless steel die head, which directly scrapes the coating on the surface of the substrate. The width and thickness of the scraping coating are adjustable; the control accuracy of the scraping coating layer is ensured, and the use is convenient and reliable.

7. The stocker adopts active control, the tension is automatically adjustable, and no counterweight is needed.

8. The tension of the whole machine adopts segmented low tension control to prevent the substrate from stretching and deformation.

| Item. | Spec. |

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Aluminum spacer width | 4-30mm |

| Speed | 0-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5KW, 50HZ |

| Dimension | 2600*680*1100mm(L*W*H) |

| Weight | 650kgs |

| Name | Brand | Original |

| PLC | KINCO | China |

| Valve | HAWE | German |

| Low voltage electrical apparatus | SIEMENS | German |

| Hydraulic and pneumatic supercharging system | MAXIMATOR | German |

| Frequency converter | KINCO | China |

| Pneumatic components(cylinder/valve) | ARTAC | Taiwan |

| Quick exhaust valve/Vacuum generator | SMC | Japan SMC |

| Travel light | OMRON | Japan |

| Optical fiber | OMRON | Japan |

Other Insulating Glass Equipment of our company:

1.Insulating Glass Production Line

2.Spacer Bending Machine

3.Desiccant Filling Machine

4.Butyl Extruder Machine

5.Insulating Glass Sealing Robot

6.Glass Washing Machine

Product Categories : Butyl Extruder Machine > New Butyl Extruder Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.