Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJBZ2535G

Brand: Lijiang

Applicable Industry: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Canada, United States, Peru, Saudi Arabia, Pakistan, India, Mexico, Spain, Argentina

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, United States, Peru, Saudi Arabia, Pakistan, India, Mexico, Spain, Argentina

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Long Service Life

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Pressure Vessel, Motor, Other, Bearing, Gear, Pump, Engine, Gearbox

Max. Glass Size: 2500mm*3500mm

Min. Glass Size: 280mm*400mm

Glass Thickness: 3-15mm

Glass Washing Speed: 2-10m/Min

Glass Conveyor Speed: 45m/Min

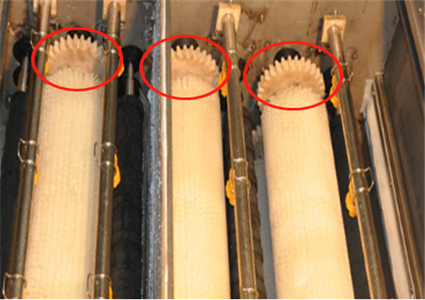

Washing Brushes: 3 Pairs

Production Name: Argon Gas Filling Machine For Insulating Glass

Dimension: 23500*3200*3700mm

Packaging: container

Productivity: 10 SETS/MONTH

Transportation: Ocean

Place of Origin: shandong,China

Supply Ability: 10 setd/month

Certificate: CE

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,EXW,CIF

Automatic Argon Gas Filling Machine for insulating glass

Production overview of Insulated Glass Production Line

Automatic insulated glass production line is mainly to glue two or more layers of flat glass with high air tightness materials around, fill the middle with dry gas, and fill the frame with desiccant to ensure the dryness of air between the glasses. Insulating glass is generally used on the walls of buildings, playing the role of heat preservation, heat insulation and sound insulation.

Washing section

1.The whole washing and drying section adopt 304 stainless steel, including the plate and interior spare parts.

The thickness plate can up to 4mm and the interior plate can be 8mm.The equipment performance is better and service life is much longer.

2. Noise reduction device

The noise can be controlled below 90 decibels by using nylon gear and sponges.

3. Water heating system

Adopts air heating system, use soft water to wash glass clearly.

4. Automatically recognize glass thickness

1). There is a universal joint device, when the glass thickness was changed, the wind knife will move forward and backward to adjust the distance so that the relative distance between the wind knife and the glass is constant, so as to avoid damage to the glass due to the changes of the glass thickness.

1) . There are chain gears on both sides of the bottom of the glass to actively transfer the glass which can keep a fast speed, not only the large size, small size glass can also be passed quickly.

Inspection section

1.The checking part uses LED tubes to check whether the glass is clean or not.

Main feature:

Automatic detect low-e & high performance glass

Wash online and offline low-e glass, automatically recognizes Low-e film

The air knife can automatically adjust the width according to the glass thickness

Using intelligent intermittent energy-saving working methods

Hierarchical type washing system

Water tank automatic temperature control, water replenishing system

European silencer system&stainless steel drying system

Technical data

| Max.glass size(Optional) | 2500*3500mm |

| Min.glass size | 280*450mm |

| Glass thickness | 3-15mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 15m/min |

| Washing brushes | 3 pairs |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 31KW |

Electrical parameters

| NAME | ORIGIN | BRAND |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Photoelectric switch | Korea | AUTONICS |

| Button and indicator light | France | SCHNEIDER |

| Touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Transfer motor | Taiwan | LINHAI |

| Brush motor | China | QINGHUA |

| Water pump | China | LINGXIAO |

| Pneumatic Components | Taiwan | AIRTAC |

| Insulating Glass Production Line |

| Insulated Glass Production Line |

| Double Glazing Glass Production Line |

| Double Glass Processing Machine |

| Spacer Bending Machine |

| Aluminum Spacer Bending Machine |

| Aluminum Spacer Bending Equipment |

| Warm Edge Spacer Bending Machine |

| Automatic Desiccant Filler |

| Automatic Desiccant Filling Machine |

| Molecular Sieve Filling Machine |

| Molecular Sieve Filling Equipment |

| Butyl Extruder Equitment |

| Automatic Butyl Extruder |

| Butyl Rubber Coating Machine |

| Custom Butyl Extruder Machine |

| Automatic Low-E Glass Edge Deletion |

| Glass Edging Machine |

| Low-E Glass Edge Remover Machine |

| Low-E Glass Edge Grinding Equipment |

| Insulating Glass Sealing Robot |

| Silicone Sealant Sealing Robot |

| Glass Sealing Robot |

| Custom Glass Sealing Robot |

Product Categories : Glass Washing Machine > Vertical Glass Washing Machine

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.