Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Applicable Industry: Hotels, Farms, Food &Amp; Beverage Shops, Restaurant, Garment Shops, Building Material Shops, Home Use, Retail, Advertising Company, Food Shop, Manufacturing Plant, Machinery Repair Shops, Printing Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Philippines, Algeria, Uzbekistan, Thailand, Viet Nam, Japan, Germany, Spain, Colombia, Nigeria, Kyrgyzstan, Uae, Russia, France, Italy, Mexico, Chile, Ukraine, United States, India, South Korea, Kazakhstan, Argentina, Pakistan, South Africa, Kenya, Indonesia, United Kingdom, Turkey, Saudi Arabia, Morocco, Bangladesh, Romania, Australia, Peru, Canada, Egypt, Brazil, Malaysia, Sri Lanka, Tajikistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Brazil, Argentina, Kazakhstan, Ukraine, South Korea, Peru, Canada, Turkey, Saudi Arabia, Chile, Kyrgyzstan, Nigeria, Uae, Indonesia, United Kingdom, United States, Pakistan, Colombia, Uzbekistan, Algeria, India, Italy, Mexico, Sri Lanka, Tajikistan, Japan, Romania, Russia, France, Germany, Spain, Bangladesh, Malaysia, Australia, Morocco, South Africa, Kenya, Philippines, Viet Nam, Thailand

Old And New: New

Machine Type: Other

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Other

Core Component Warranty Period: 1 Year

Core Components: Pressure Vessel, Gear, Plc, Pump

Production Name: Automatic butyl extruder machine

Belt: Non stick belts

Glue Barrel: 7 kg

Machine Control: PLC and servo motor

Machine Brand: LIJIANG GLASS

Working Speed: 47m/min

Transportation: Ocean

Port: qingdao

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Automatic Butyl Glue Coating Machine for aluminum spacer butyl extruder

Automatic Butyl Extruder Machine is the necessary equipment for manufacturing aluminum-frame type insulated glass, even it is necessary for Vertical insulating glass processing line.The butyl that be glued on the both side of aluminum frame automatically, the glue is the first coating sealant for insulating glass. So the quality of the butyl directly decides the quality of insulating glass and using life. The butyl extruder machine have many types in the market, including manual and automatic butyl coating machines.

Function description of Automatic Butyl Extruder Machine

Butyl extruder machine has kinds of functions, please see the below instructions:

The Details Of Automatic Butyl Extruder Machine LJTB 01

Main feature :

• PLC control system, KINCO touch screen interface

• Hydraulic system using German brands

• Alarm system, reminding adding butyl glue

• The sensor can automatically measure the width of frame, the distance of nozzle can be adjustable

• Exhaust function

• Short preheating time, improve work efficiency

• Coating shape frames, the roller device can be selected at will

• Fast coating speed, can up to 47m/min

• Stable pressure and even coating

• Saving glue. The amount of glue on both sides can reach 4g / m

• Big glue barrel, 200L. (Optional)

Technical data :

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 6A - 27A |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Electrical parameters

| Name | Original | Brand |

| PLC | China | KINCO |

| Valve | German | HAWE |

| Low voltage electrical apparatus | German | SIEMENS |

| Hydraulic and pneumatic supercharging system | German | MAXIMATOR |

| Frequency converter | China | KINCO |

| Pneumatic components | Taiwan | ARTAC |

| Quick exhaust valve/Vacuum generator | Japan SMC | SMC |

| Travel light | Japan | OMRON |

| Optical fiber | Japan | OMRON |

Machine details of Aluminum spacer butyl extruder machine

1.KINCO Touch Screen

Clear interface, Simple operation, Smart touch screen,Updated programming

2.Adopt Germany Siemens brand, stable performance.

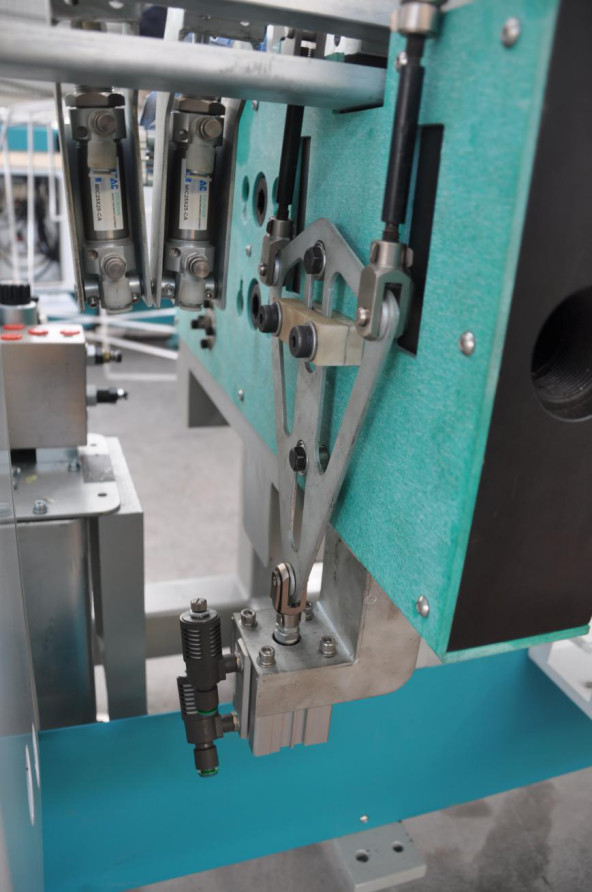

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

3.Automatic filter function

Automatically filter debris, keep spreading evently.

4.Glue cylinder

Adopt the upright structure, easy to change butyl.

5.Germany HAVE Valve

Adopt Germany’s Harvey valve, more stable performance.

6.Alarm system

Automatically alarm system, reminding adding butyl.

7.Guiding Wheel

Using guiding wheel to help arc frames coating.

8.Germany Maximator Cylinder

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

Related products of LIJIANG GLASS

Automatic Aluminum Spacer Bending Machine LJZW2020

Automatic aluminum Spacer Bending Machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Main features

Tech parameters of High speed butyl extruder machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Product Categories : Butyl Extruder Machine > Automatic New Butyl Extruder Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.