Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: Jinan Lijiang Glass

Applicable Industry: Other, Hotels, Restaurant, Garment Shops, Home Use, Advertising Company, Retail, Building Material Shops, Food Shop, Printing Shops, Manufacturing Plant, Construction Works, Machinery Repair Shops, Energy &Amp; Mining, Food &Amp; Beverage Factory, Farms, Food &Amp; Beverage Shops

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Brazil, Malaysia, Sri Lanka, Tajikistan, Romania, Australia, Peru, Canada, Turkey, Saudi Arabia, Morocco, Bangladesh, Kenya, United Kingdom, Indonesia, South Africa, Argentina, Pakistan, United States, Kazakhstan, South Korea, India, Italy, Mexico, Chile, France, Russia, Uae, Kyrgyzstan, Ukraine, Spain, Colombia, Nigeria, Uzbekistan, Algeria, Thailand, Viet Nam, Philippines

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Kazakhstan, Argentina, Canada, Peru, Brazil, Egypt, South Korea, Ukraine, Saudi Arabia, Turkey, Chile, Kyrgyzstan, Uae, Indonesia, United Kingdom, Nigeria, Colombia, Pakistan, United States, Uzbekistan, Algeria, India, Italy, Mexico, Sri Lanka, Tajikistan, Romania, Russia, France, Malaysia, Bangladesh, Spain, Australia, Thailand, Viet Nam, Philippines, Kenya, South Africa, Morocco

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce, Pda

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-25mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Pressure Vessel, Motor, Other, Bearing, Gear, Plc, Pump, Engine, Gearbox

Type: Insulating Glass Production Line

Structure: Vertical

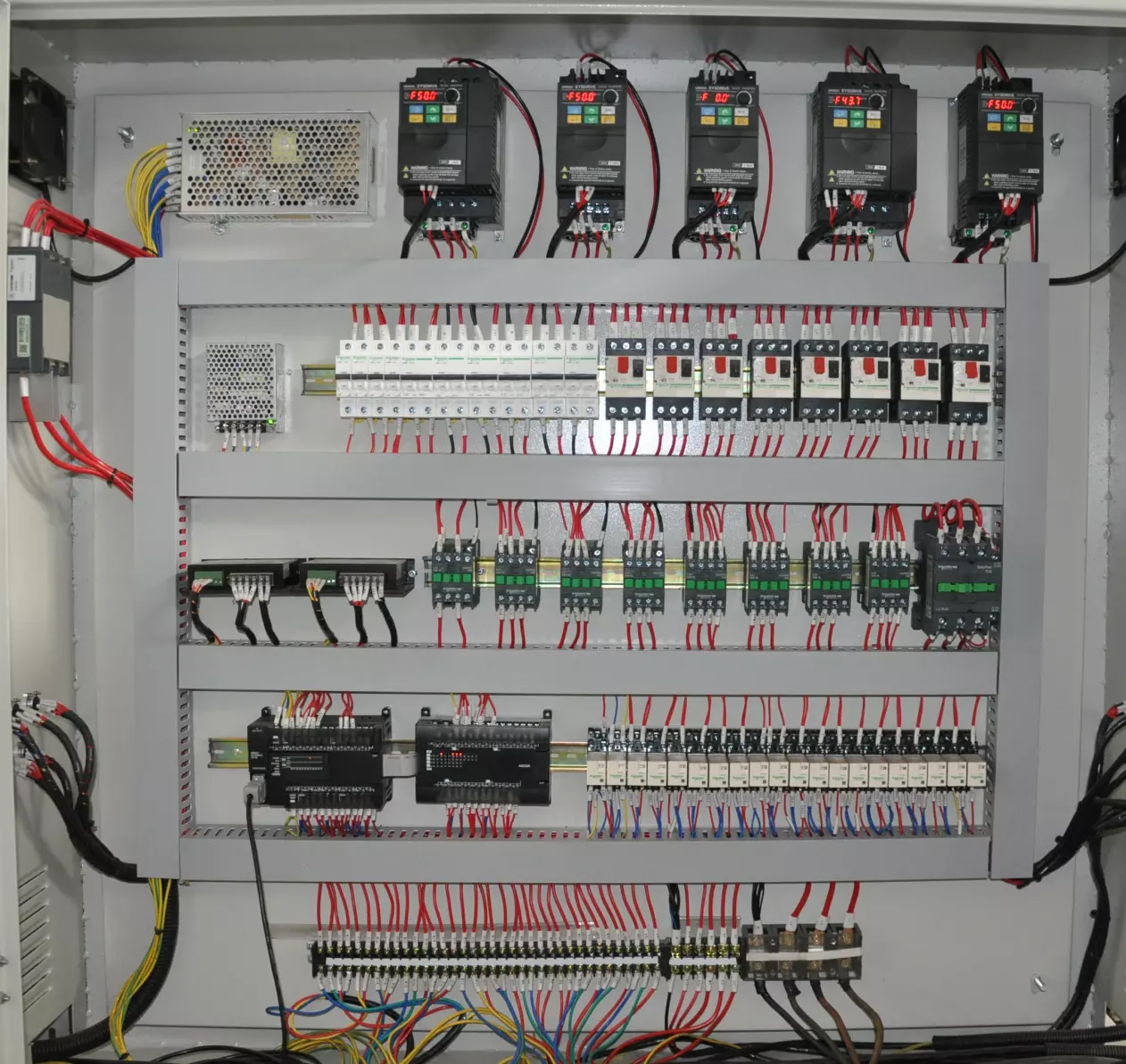

Control System: Plc

Glass Washing Machine Type: Horizontal Glass Washing Machine

Grinding Head Number: 16

Condition: New

Operation Method: Plc

Washing Speed: 2-10m/Min

Color: Customers' Request

Packaging: Wooden Cases Package and Container Transfer

Productivity: 150 sets on per year

Transportation: Ocean,Land,Air,Others

Place of Origin: Jinan City, Shandong Province, China

Supply Ability: 5 sets on 30 working days

Certificate: CE & ISO9000

Port: Qingdao Port,Tianjin Port,Shanghai Port

Payment Type: L/C,T/T,D/P,Paypal,D/A,Others

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,FAS,DEQ,DDP,DDU,Express Delivery,DAF,DES

Vertical hollow glass double inflation flat pressing production line used in hollow glass processing and production

| Max.glass size | 2500mm*4500mm |

| Min.glass size | 280mm*400mm |

| Glass thickness | 3-15mm / 19mm |

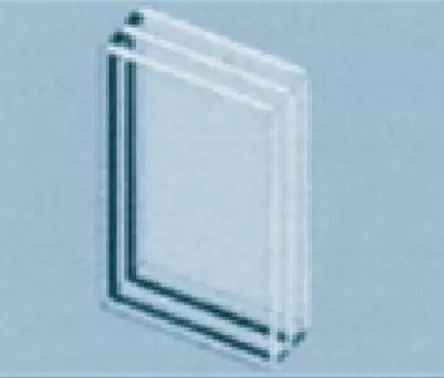

| Insulating glass thickness | 50mm / 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50Hz 40Kw |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kgs |

1.The vertical hollow glass automatic production line includes the feeding section, cleaning and drying section, discharging section 1, discharging section 2, inspection and framing section, flat pressing feeding section, inflatable plate pressing section and flat pressing section.

2.The insulating glass production line adopts Siemens control system and is equipped with high-resolution touch screen. The operator can modify the working parameters of the production line at any time.

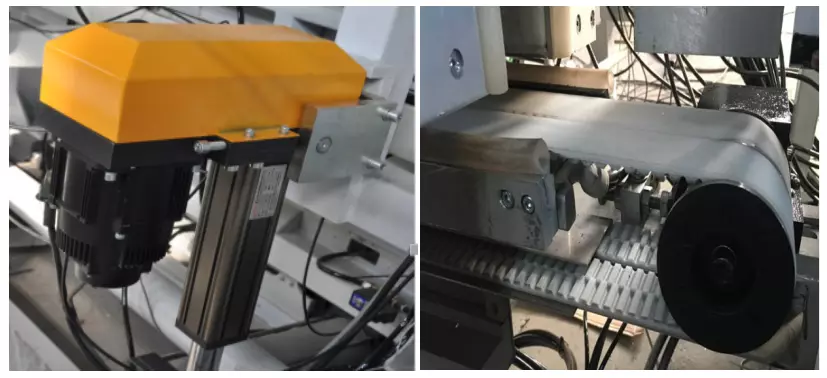

3.The feeding section adopts stepless frequency control, the glass can run smoothly at a suitable speed, and the coating detection and alarm system can timely and accurately detect whether the coating surface of the coated glass is placed correctly or not.

The production line can do double glass,triple glass and stepped glass.

We adopt CNC technology into the pressing board. We designed the adjustable points inside the pressing board to keep the back plate straight all the time. In China, except LIJIANG, no one can guarantee that the pressing board will remain vertical and straight all the time after used 10 or 20 years. However, we solve this problem already.

Series products:

Automatic Low-E Glass Deletion

Insulating Glass Sealing Robot

Glass Lifter

Glass Cutting Machine

Glass Edge Finishing Machine

Product Categories : Insulating Glass Production Line > Air Floating Insulating Glass Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.