Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Applicable Industry: Hotels, Building Material Shops, Manufacturing Plant, Garment Shops, Machinery Repair Shops, Food Shop, Farms, Restaurant, Other

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, France, Saudi Arabia, Spain, Kenya, Algeria, Kazakhstan, Tajikistan, Ukraine, Sri Lanka, Argentina, Thailand, Canada, Indonesia, Turkey, Viet Nam, Pakistan, South Korea, Romania, Kyrgyzstan, Nigeria, Bangladesh, Chile, Malaysia, Philippines, United Kingdom, India, Australia, Uae, Uzbekistan, Morocco, Russia, Peru, United States, South Africa, Mexico, Brazil

Showroom Location (in Which Countries Are There Sample Rooms Overseas): France, Egypt, Spain, Saudi Arabia, South Africa, Uae, Uzbekistan, Tajikistan, Kazakhstan, Colombia, Thailand, Indonesia, Canada, Turkey, Viet Nam, Pakistan, Argentina, Kenya, Algeria, Ukraine, Sri Lanka, Malaysia, Kyrgyzstan, Romania, India, Philippines, United Kingdom, United States, Brazil, Mexico, South Korea, Bangladesh, Nigeria, Australia, Morocco, Chile, Russia, Peru

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor, Other, Pump, Plc

Packaging: container

Transportation: Ocean

Supply Ability: 3sets/month

Port: qingdao

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,EXW,CIF

Touch Screen operating convenient Insulating Glass processing line with 98% Argon gas filling

The LJBZ2570PG automatic vertical Insulating Glass Production Line has the following functions: washing flat glass, installing aluminum frames, pressing ordinary insulating glass units, pressing double insulating glass units, and pressing double-layer three-layer insulating glass units.

LJBZ2570PG is special equipment for producing aluminum tape insulating glass, which has the advantages of small footprint, reliable performance, high efficiency, and convenient maintenance.

Main feature of Jumbo size insulating glass production line

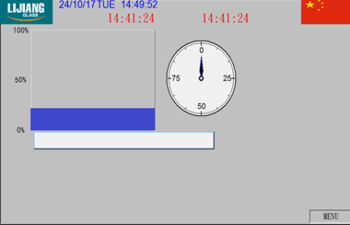

● Touch screen interface, German Siemens PLC control system

● Automatic recognition of coated glass and Low-E glass

●Washing machine adopts SS material and waterproof device

Water tank with automatic temperature control and water flushing system

● 3 pairs of soft brushes can clean Low-E glass online and offline

●Fan automatic start and stop setting

● Air heating system

●Noise reduction system

●Online display of washing speed

●Adjustable pressure plate, keep the pressure plate surface straight

● Aviation plug connection method

Suitable for the production of triple insulating glass and special-shaped insulating glass

●Intelligent intermittent work to save energy

Main parameters of Automatic insulating glass processing line

| Power supply | Voltage | 380 |

| Frequency | 60 | |

| Total power | kW | ≈42 |

| Washing speed | m/min | 2~10 |

| Max.working speed | m/min | 45 |

| Min.glass size | mm | 450×280 |

| Max.glass size | mm | 2500×7000 |

| Washing glass thickness | mm | 3~15 |

| Max.insulating glass thickness | mm | 60 |

| Conveyor height | mm | 500 |

| Total gas consumption | L/min | 1500 |

Insulating glass processing machine adopts Siemens control system, equipped with high resolution touch screen, the operator can modify the working parameters of the production line at any time, and can clearly display the status of each input and output signal, which is convenient for the routine maintenance of the machine.

LJBZ2570PG Unloading section.

LJBZ2500PG is not suitable for bow-shaped glass or twisted glass, because the plane in the pressed part is immutable.

LJBZ2500PG is a press with a new type of inflation technology. This equipment is suitable for high-tech glass press inflators of various gases or mixed gases. Because before each gas or mixture is filled with insulating glass, the control system will detect the preset gas type (including the mixing ratio of the mixed gas) and flow rate.

LJBZ2500PG glass pressing and inflating section is suitable for pressing double insulating glass units or three-layer insulating glass units at the same time. This machine can press all kinds of flat glass (including coated glass and laminated glass).

LJBZ2500PG can be used to measure the gas concentration of insulating glass online. The measuring device in front of the equipment can accurately measure the size and thickness of the glass and calculate the amount of gas required.

LJBZ2500PG can simultaneously press gas into two hollow glass units with a length of less than 1.5m, which greatly improves production efficiency, especially for glass with a length of less than 1.5m.

Main Features

• Two pieces of insulating glass are pressurized and inflated at one time, and each piece of insulating glass is filled with more than 90% of argon gas

• Pressing two pieces of IGU at a time can better prevent deformation of the pressed part. Each 1m*1m double glass can reach 27s, which greatly improves work efficiency

• High-speed IG processing line, obtained Chinese patent in 2019

• From the conveying part to the pressing part, each part is separated

• Suitable for mass production in factories. Super fast speed

• Solve the problem of sealing robot waiting for work. One worker installs two spacer frames for two IGUs

• ERP system automatically measures glass size and labeling (labeling before and after pressing) (optional)

Technical data

| Max. glass size | 2500mm*7000mm |

| Max glass size for filling gas | 2500mm*7000mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 54.5KW |

| flat glass thickness | 3-30mm |

Other products of LIJIANG GLASS

Argon Gas Filling Machine with touch screen

This argon gas filling machine is manual filling machine, but it has the touch screen to display how much the argon gas value. And this filling machine can set how much gas value you want to fill into insulating glass.

Types of the argon gas filling machine

General manual argon gas filling machine & new fast argon gas filling machine

Insulating Glass Manual Argon Gas Filling Machine For Filling Argon Gas

The type of LJCJ02 smart insulating glass gas filling machine is a special equipment for filling insulating glass. The device by microcomputer and imported from the sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic concentration adjustable, charging efficiency is high, the operation is simple. It is essential to further improve the performance of the hollow glass equipment.

1. Main feature

• It is used for filling Argon into insulating glass

• High effectively, allowed for four pieces of IGU

• When the gas is full, it will alarm and stop automatically

• Can set and display the data of gas value

2. Specifications and technical date :

| Item | Value |

| Power supply | AC220 V 50Hz |

| 0.5kw | |

| Contour dimension | 600X400X1210mm |

| Machine net weight | 40kg |

Relative machines:

Product Categories : Insulating Glass Production Line > Insulating Glass Production Line2025

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of insulating glass machinery, aluminum-plastic windows & doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive glass processing solution and windows & doors solution for domestic and foreign customers well.So far, we have independently produced Insulating Glass Production Line,Insulating Glass Sealing Robot, Spacer Bending Machine , Desiccant Filling Machine, Butyl Extruder Machine,Glass Cutting Machine, its technology and quality have reached the highest leading level in China. Until 2019, we exported glass machines and materials to America, South America, Europe, the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect international business relationship with 10 powerful agents and made an endeavor together to build a famous international brand to the world.

Kation-Tech, with craftsmanship, profession and honesty, wins the future with you together!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD is our factory. It is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.